歡迎來到北京中航時代儀器設備有限公司網站!

歡迎來到北京中航時代儀器設備有限公司網站! 咨詢電話:13699145010

咨詢電話:13699145010 歡迎來到北京中航時代儀器設備有限公司網站!

歡迎來到北京中航時代儀器設備有限公司網站! 咨詢電話:13699145010

咨詢電話:13699145010產品分類

Product Category詳細介紹

| 品牌 | AIRTIMES/中航時代 |

|---|

ZJC-50KV耐電壓擊穿測試儀滿足標準:

1、GB1408.1-2006《絕緣材料電氣強度試驗方法》

2、GB1408.2-2006《絕緣材料電氣強度試驗方法

第2部分:對應用直流電壓試驗的附加要求》

3、GB/T1695-2005《硫化橡膠工頻擊穿電壓強度和耐電壓的測定方法》

4、GB/T3333 電纜紙工頻電壓擊穿試驗方法

5、HG/T 3330絕緣漆漆膜擊穿強度測定法

6、GB12656 電容器紙工頻電壓擊穿試驗方法

7、ASTM D149《固體電絕緣材料工業電源頻率下的介電擊穿電壓和介電強度的試驗方法》

ZJC-50KV適用范圍

主要適用于固體絕緣材料(如:塑料、橡膠、層壓材料、薄膜、樹脂、云母、陶瓷、玻璃、絕緣漆等絕緣材料及絕緣件)在工頻電壓或直流電壓下擊穿強度和耐電壓的測試。

本儀器由電腦控制,是我公司自主研發的全新第三代介電擊穿檢測儀器,本儀器電子控制系統是通過西門子PLC控制,數據采集方式通過光電隔離,有效解決試驗過程中的抗干擾問題,軟件操作使用方便,能夠實時顯示動態曲線,同時升壓速率無級可調,可以根據自己的需要進行升壓速率調節,調節范圍在10V-5000V/S,處于國內地位(國內*能達到此功能的廠家),使升壓速率真正做到勻速、準確,并能夠準確測出漏電電流的數據。可實時繪制試驗曲線,顯示試驗數據,判斷準確,并可保存,分析,打印試驗數據。

本系統能夠自動判別試樣擊穿并采集擊穿電壓數據及泄露電流,同時能夠在擊穿的瞬間電壓迅速降低自動歸零。軟件系統操作方便,性能穩定,安全可靠。

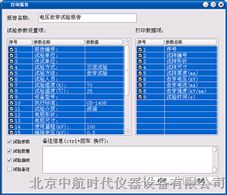

ZJC-50KV軟件功能:

01、軟件平臺:WINDOWS窗口操作平臺,界面直觀,便于操作

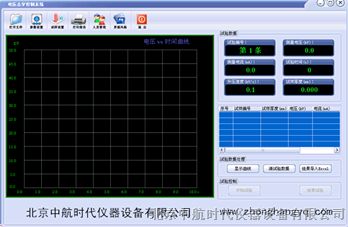

02、曲線顯示:在實驗過程中可以動態顯示試驗曲線

03、數據導出:可以對試驗結果導入EXCEL表格

04、實驗報告:可以人為設置報告名稱,并對實驗報告進行打印

05、試驗方式:可以根據需求對直流試驗和交流試驗進行靈活選擇

06、試驗方法:可以根據需求自行選擇擊穿電壓、耐壓試驗、梯度試驗

07、參數設置:可以根據不同的試驗方式及試驗方法靈活設置所需的不同參數值

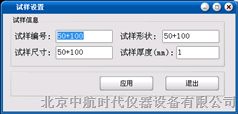

08、試樣設置:可對不同標準的試樣參數靈活設置

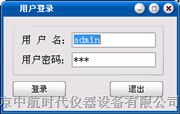

09、人員管理:設置用戶名及密碼,不同的操作員登入進行不同的試驗,互不影響

10、標準選擇:含有不同標準,可根據需求自行選擇

11、連續操作:連續操作試驗時,可直接在軟件里結束試驗,進行二次試驗

ZJC-50KV技術要求:

01、輸入電壓: 交流220 V

02、輸出電壓: 交流 0--50 KV

直流0—50 KV

03、電器容量: 3KVA

04、擊穿zui大輸出電流:100mA 30mA 可調換

05、高壓分級: 0--5KV; 0-10KV;0-30KV; 0-40KV; 0-50KV,0-50KV;

06、升壓速率: 10V/S 100V/S 200V/S 500V/S 1000V/S 2500V/S 3000V/S 可手動設置

07、試驗方式:

直流試驗:1、擊穿試驗 2、梯度升壓 3、耐壓試驗

交流試驗:1、擊穿試驗 2、梯度升壓 3、耐壓試驗

08、擊穿判停方式:1、電壓判停 2、電流判停

09、電壓試驗精度: ≤ 1%

10、試驗方式:1、絕緣試樣空氣中試驗2、絕緣試樣浸油中試驗

11、黃銅電極規格: ¢25mm 兩個 ¢75mm一個

12、主機尺寸:長寬高約700*800*1500(MM)

13、操作臺尺寸:長寬高約700*800*700(MM)

14、防護罩材質:亞克力

15、設備重量:約100KG

ZJC-50KV安全保護:

本儀器具有比較完善的安全防護措施:

本儀器具有多重防護措施,保證操作人員的人身安全

1、門限位保護:不關門,即使通電點實驗開始,設備無任何反應,軟件有:安全門未關閉提示。

2、電壓歸零保護:如果在實驗過程中,突然斷電,下次開機后,會自動回到零位,保證初始電壓為 在零位

3、終止電壓保護:可以通過軟件設定終止電壓,保證在升壓過程中如果出現異常升到的電壓后,自動終止并歸零

4、高壓機械限位:如果軟件系統失去控制,電壓繼續往上升,到高壓限位后自動歸零

5、如果在擊穿后未判停,通過過流保護器采集數據保證電壓自動歸零

6、有高壓指示燈,通過觀察指示燈的狀態來判斷實在升壓還是在零位

7、如果長時間做實驗,為保證設備的良好運行,設備留有變壓器排氣口,保證變壓器的良好運行,

增長使用壽命

8、如果在實驗中,試樣有異味或者出現燃燒和冒煙現象,可以通過排風系統進行排除。

9、獨立接地保護

10、短路保護

11、軟件誤操作保護

12、漏電保護

13、實驗結束放電保護

ZJC-50KV配置

| 序號 | 名稱 | 數量 |

| 01 | 試驗主機 | 一臺 |

| 02 | 控制裝置 | 一套 |

| 03 | 試驗電極 | 二套(三只) |

| 05 | 放電系統 | 一套 |

| 06 | 控制系統 | 一套 |

| 07 | 數據采集系統 | 一套 |

| 08 | 試驗軟件 | 一套 |

| 09 | 產品使用說明書 | 一份 |

| 10 | 保護電阻 | 一個 |

| 11 | 產品合格證 | 一份 |

| 12 | 絕緣油油槽 | 一套 |

| 13 | 聯想電腦 | 一臺 |

| 14 | 噴墨打印機 | 一臺 |

參數設置:

曲線顯示

打印報告:

油中試驗

測試電極符合國標1408要求

售后服務承諾

一、安裝調試:協助試驗機的安裝,負責試驗機的運輸、調試。

二、驗收標準:試驗機按訂貨技術附件進行驗收。終驗收在買方進行,對用戶提供的試樣進行試驗,并提供測試報告。

三、培訓:安裝調試同時,在儀器操作現場一次性免費培訓操作人員2-3名,該操作人員應是由需方選派的長期穩定的員工,培訓后能夠對設備基本原理、軟件使用、操作、維護事項理解和應用,使人員能夠獨立操作設備對樣品進行檢測、分析,同時能進行基本的維護。

四、軟件升級:終生免費提供新版本控制軟件。

五、保修:

1、設備保修兩年,終身服務,兩年內非人為損壞的零部件免費更換,保修期內接到用戶邀請后, zui遲響應時間為2小時內,在與用戶確認故障后,我公司會在48小時內派工程師到達現場進行免費服務,盡快查清故障所在位置和故障原因,并向用戶及時報告故障的原因和排除辦法 。

2、保修期內人為損壞的零部件按采購(加工)價格收費更換。

3、保修期外繼續為用戶提供優質技術服務,在接到用戶維修邀請后3天內派工程師到達用戶現場進行維修。并享有優惠購買零配件的待遇。

4、傳感器過載及整機電路超壓損壞不在保修范圍內。

六、售后管理:

我公司實現計算機化管理,實行客戶定期回訪制度,定期復查設備的工作情況,定期指導用戶對設備進行保養和檢測,以便設備正常運轉,跟蹤客戶的設備使用情況,以便及時對設備進行維護

One, meet the standard:

1, GB1408.1-2006 "electrical insulation strength material test method"

Test methods for electrical strength of 2, GB1408.2-2006 "insulation materials

The second part: Additional requirements for tests using direct voltage "

3, GB/T1695-2005 "vulcanized rubber power frequency voltage breakdown strength and voltage resistance determination method"

4, GB/T3333 cable paper power frequency voltage breakdown test method

5, HG/T 3330 insulation paint film breakdown strength determination method

6, the GB12656 capacitor paper power frequency voltage breakdown test method

Test methods of solid electrical insulating materials industrial power frequency dielectric breakdown voltage and dielectric strength of 7, ASTM "D149"

Two, the scope of application

Mainly applicable to solid insulation materials (such as: plastic, rubber, lamination material,film, resin, mica, ceramic, glass, insulating paint and other insulation material and insulation parts) in the frequency of the voltage or DC voltage breakdown strength and voltage withstand test.

The instrument is controlled by computer, is my company independent research and development of the new third generation dielectric breakdown testing instrument, the instrument of electronic control system is controlled by Siemens PLC, data acquisition modethrough a photoelectric isolation, effectively solving the problem of anti-interference ofsoftware test process, convenient in operation, can display real-time dynamic curve, while the rate of pressure rise stepless adjustable, can according to their own needs to boost rate adjustment, adjustment range in 10V-5000V/S, in the domestic leading position (the onlydomestic manufacturers can achieve this function), so that the pressure rate truly uniform,accurate, and can accuray measure the leakage current data. Real-time mapping test curve, test data show that, to judge accuray, and can save, print the test data analysis.

The system can automatically distinguish the sample breakdown and breakdown voltage andleakage current data acquisition, and can rapidly reduce auto zero at the moment of the voltage breakdown. The software system is easy to operate, stable performance, safe and reliable.

Three, the software function:

01, the software platform: WINDOWS windows operating platform, intuitive interface, easy operation

02, curve display: during the experiment can dynamically display the test curve

03, data export: can the test results into EXCEL table

04, experimental report: can be artificially set the report name, and print the test report

05, test mode: can flexibly select for DC test and AC test according to the requirements of

06, test methods: you can choose the breakdown voltage, voltage withstand test, gradient test according to the requirements of

07, the parameter settings: you can test different ways according to different parameters and test methods flexibly set the required value

08, sample set: on the specimen parameters of different standard flexible settings

09, personnel management: set the username and password, different operators in differenttest, mutual influence

Selection criteria: 10, with different standards, can choose according to need

11, continuous operation: continuous operation test, may be the end of the test directly in software, carries on two times of test

Four, the technical requirements:

01, the input voltage: AC 220 V

02, the output voltage: AC 0--50 KV

DC 0 - 50 KV

03, electrical capacity: 3KVA

04, the breakdown of the maximum output current: 100mA 30mA convertible

05, high grade: 0--5KV; 0-10KV; 0-30KV; 0-40KV; 0-50KV, 0-50KV;

06, the rate of pressure rise: 10V/S 100V/S 200V/S 500V/S 1000V/S 2500V/S 3000V/S can be set manually

07, test methods:

DC test: 1, breakdown test 2, pressure gradient, pressure test 3

AC test: 1, breakdown test 2, pressure gradient, pressure test 3

08, breakdown judgment stops: 1, stop 2, current voltage convicted sentenced to stop

09, voltage test accuracy: less than 1%

10, test methods: 1, insulation, insulation test specimen in 2 oil immersion test samples in air

11, brass electrode specifications: Phi 25mm two of 75mm a

12, the host size: length width height is about 700*800*1500 (MM)

13, the operating table size: length and width and height of about 700*800*700 (MM)

14, the protective cover material: acrylic

15, weight: about 100KG

Five, security protection:

The instrument has a relatively perfect safety protection measures:

This instrument has multiple protective measures to ensure the personal safety of operators

1, limit protection: not closed, even if the electricity point at the beginning of the experiment,without any reaction, equipment software: security door not closed tips.

2, voltage zero protection: if a sudden power failure in the course of the experiment, the next boot, will automatically return to zero, ensure the initial voltage is at zero

3, the termination voltage protection: can terminate the voltage through the software setting,guarantee in the boosting process if an exception occurs up to a specified voltage,automatically terminate and return to zero

4, high pressure mechanical limit: if you lose control software system, voltage to continue to rise, to the high-pressure limit after the automatic zero

5, if not found parked in the breakdown, through the overcurrent protective device data collection to ensure the voltage auto zero

6, there is high pressure indicator light, light by observing the state to determine really boostor at zero

7, if a long time to do the experiment, in order to ensure a good operation of equipment,equipment have transformer exhaust port, to ensure the good operation of transformer,

An increase of service life

8, if in the course of the experiment, samples have peculiar smell or the emergence ofcombustion and smoke phenomenon, can be ruled out through the ventilation system.

9, independent earthing protection

10, short circuit protection

11, software protection misoperation

12, leakage protection

13, the end of the experiment the discharge protection

產品咨詢

電話

微信掃一掃